The food packaging market is undergoing burgeoning development, with a projected market value of $478.18 billion in 2028. Along with the rapid growth, some changes in the packaging market need our attention, one of which is the increasing demand for convenient and green food packaging. Such great demands boost the development of related packaging solutions, one of which is the peel-off ends. So in case people have no idea about it, here we will give a deep insight into this packaging solution and see why it occupies an important position in the aluminum food packaging market.

(Copyright photo from https://www.freepik.com/free-photo/concept-tasty-snack-with-sandwiches-with-sprats-wooden-background_21649751.htm#page=3&query=can%20food&position=18&from_view=search&track=sph)

Things You Should Know about Easy Peel-off End

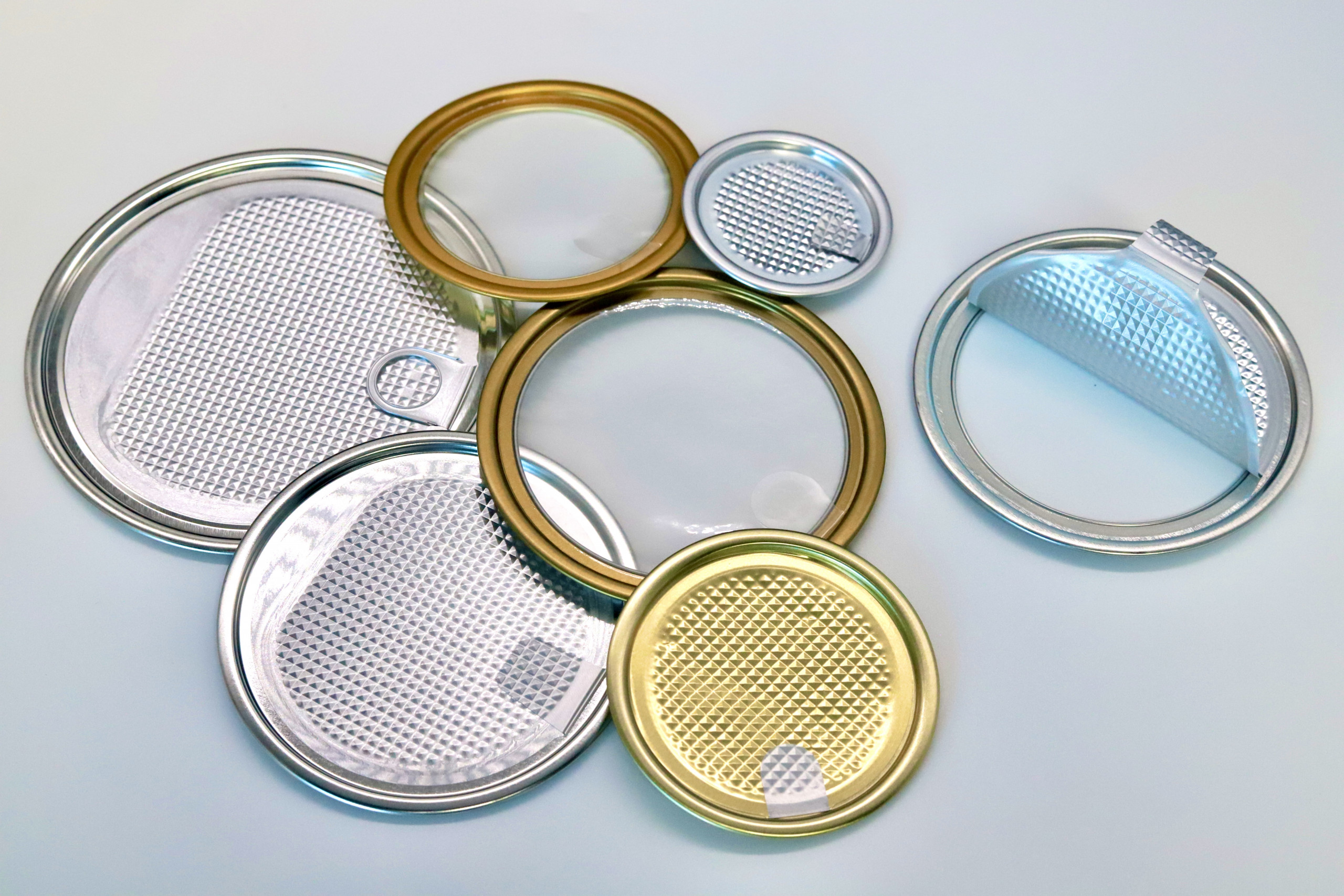

Peel-off ends, also known as easy peel, PO, POE, or aluminum foil ends, are metal packaging with high sealing and pressure resistance used in food canned packaging. Now let’s go further into its manufacturing process and types.

1.Manufacturing Process of Easy Peel-off Ends

Step 1: The process starts with coil cutting – this involves cutting the tinplate coils and forming a package.

Step 2: Then, the can must be completely varnished.

Step 3: After that, it’s necessary to cut the sheets into strips in the first machine of the manufacturing line.

Step 4: The next step involves cutting the bands into the shape of the cover.

Step 5: Conveyor belts, then transfer the sketches to the gumming machines. Then, on the container, they go through a process to ensure an airtight lid closure.

Step 6: After that, the cover and the ring go on a multi-station press where the manufacturing happens.

Step 7: Finally, the can is re-varnished to eliminate oxidation and goes through quality control and inspection before going to the market.

2.Main Types of Easy Peel-off Ends

。The peel-off end is commonly used for dry food, such as snack food and milk powder. This type is not processed at high-temperature sterilization.

。The peel-off end is also applicable to the retort food, such as meat and fish. It endures incredibly high temperatures throughout the sterilizing process.

。Peel-off end with valve also applies to canned coffee. This type of easy peel-off end can better preserve the quality of the dry food for a long time.

Peel-off End, a Worthy Investment in Aluminum Food Packaging Solutions

As stated below, peel-off ends, one of the aluminum food packaging, is sought-after for their great performance.

1.Ductility

Aluminum has a low melting point while, at the same time, being very ductile and easy to mold, giving aluminum packaging an advantage from a marketing perspective. Peel-off ends can be easily customized with creative patterns, embossing, and printing for brand identification and consumer appeal.

2.Convenience

The peel-off end is made of soft aluminum foil or composite film. It will be easier for you to consume in the future because the end that you peeled off is so simple to open. The market of peel-off ends has slowly begun to take notice of and will be applied widely to adapt to older people, children, and women.

3.High Barrier Protection

The peel-off ends give the highest possible freshness and taste retention in the fast-moving consumer goods (FMCG) and food industries. The ends can help keep food fresh by keeping the food from coming into contact with air and moisture, and, in turn, the growth of bacteria would make the food unfit for consumption.

Top 4 Considerations While Selecting a Peel-off End Manufacturer

Finding the most suitable peel-off ends manufacturer seems overwhelming. So here are some supplier selection criteria when people look for aluminum food packaging suppliers.

1.Experience

When selecting particular easy-open-ends suppliers, ensure they have enough working experience in the aluminum food packaging industry. Having been committed to the aluminum food packaging industry, we have formed a professional R&D team that will add value to companies and makes everything run smoothly.

2.Equipment

Ensure the potential supplier has all the equipment, tools, and talent to meet requirements as advanced equipment guarantees capacity. With 6 advanced automated production lines, we can achieve a greater output while maintaining the same high-quality product.

3.Quality

Quality is very basic and non-negotiable for businesses looking for a supplier. Thus, the aluminum food packaging supplier must be consistent regarding the quality of the packaging item. As a reliable packaging supplier, we never hesitate to invest in advanced production products. Equipped with advanced international cutting, coating, and printing equipment and can lid production equipment, we can produce premium lids for cans.

4.Delivery and Service

Aluminum food packaging must be readily available to deliver to clients on time. Located in EOE industrial zone, we can react fast to customer needs and customization services. The samples can be ready for delivery in 7-15 working days after you pay the sample charge and send us confirmed files.

Canlid Industries, a Professional Peel-off Ends Supplier for Your Choice

Canlid Industries, focusing on aluminum food packaging, offers a collection of research and development, production, and sales as a reliable food packaging manufacturer. We provide adequate and consistent peel-off ends for our customers with advanced production and testing equipment. By virtue of geography and transportation, the orders can be delivered on time, thus guaranteeing sufficient supply for you. Additionally, we have attractive and reasonable prices to earn your reliance and follow-on orders.